Unpacking The 'JIT Meaning': From Slang To Supply Chains

In the vast landscape of modern communication and business, certain terms carry surprising weight, often possessing multiple layers of meaning depending on the context. One such intriguing term is "jit." While it might sound like a simple, three-letter word, the "jit meaning" can swing wildly from a casual piece of Gen Z slang to a fundamental pillar of global manufacturing and supply chain efficiency. Understanding these diverse interpretations is not just a linguistic exercise; it's crucial for navigating both social interactions and complex economic landscapes.

This comprehensive guide will delve deep into the multifaceted world of "jit," exploring its dual identity. We'll uncover its origins as a contemporary slang term, often heard among younger generations, and then pivot to its profound significance in the business realm, particularly within inventory management and logistics. By the end, you'll have a clear grasp of what "jit" truly means, whether you're deciphering a text message or analyzing a company's operational strategy.

Table of Contents

- Understanding the Dual "JIT Meaning"

- JIT in Business: The Just-In-Time Inventory System

- The Historical Roots of Just-In-Time

- How Just-In-Time (JIT) Works in Practice

- Advantages of Embracing the JIT Philosophy

- Navigating the Challenges of JIT Implementation

- JIT Beyond Inventory: A Broader Business Perspective

- The "Jit" Slang: A Deeper Dive

Understanding the Dual "JIT Meaning"

The term "jit" presents a fascinating case study in linguistic evolution and contextual interpretation. On one hand, it's a casual, often playful, word used in everyday conversation. On the other, it's a highly technical acronym that underpins the efficiency of some of the world's largest corporations. To truly grasp the "jit meaning," we must first acknowledge these two distinct identities. For many, especially members of Generation Z, "jit" is a piece of slang commonly used to refer to a young person, typically a teenager, or someone who is inexperienced or new at something. It's a colloquialism that can be used affectionately, dismissively, or simply descriptively. Imagine a seasoned gamer calling a new player a "jit," or a parent referring to their energetic child as a "little jit." As the Redkiwi English Guide points out, it's about understanding the meaning, origin, examples, and context for this slang phrase. This usage is informal, fluid, and largely confined to social interactions. However, step into the world of business, manufacturing, or supply chain management, and the "jit meaning" undergoes a complete metamorphosis. Here, JIT stands for "Just-In-Time," a revolutionary inventory management philosophy that has reshaped global commerce. It's a strategy focused on efficiency, waste reduction, and responsiveness. The contrast couldn't be starker: from a casual descriptor of youth to a rigorous operational methodology. Our exploration will now primarily focus on this powerful business application, while later circling back to fully appreciate its slang counterpart.JIT in Business: The Just-In-Time Inventory System

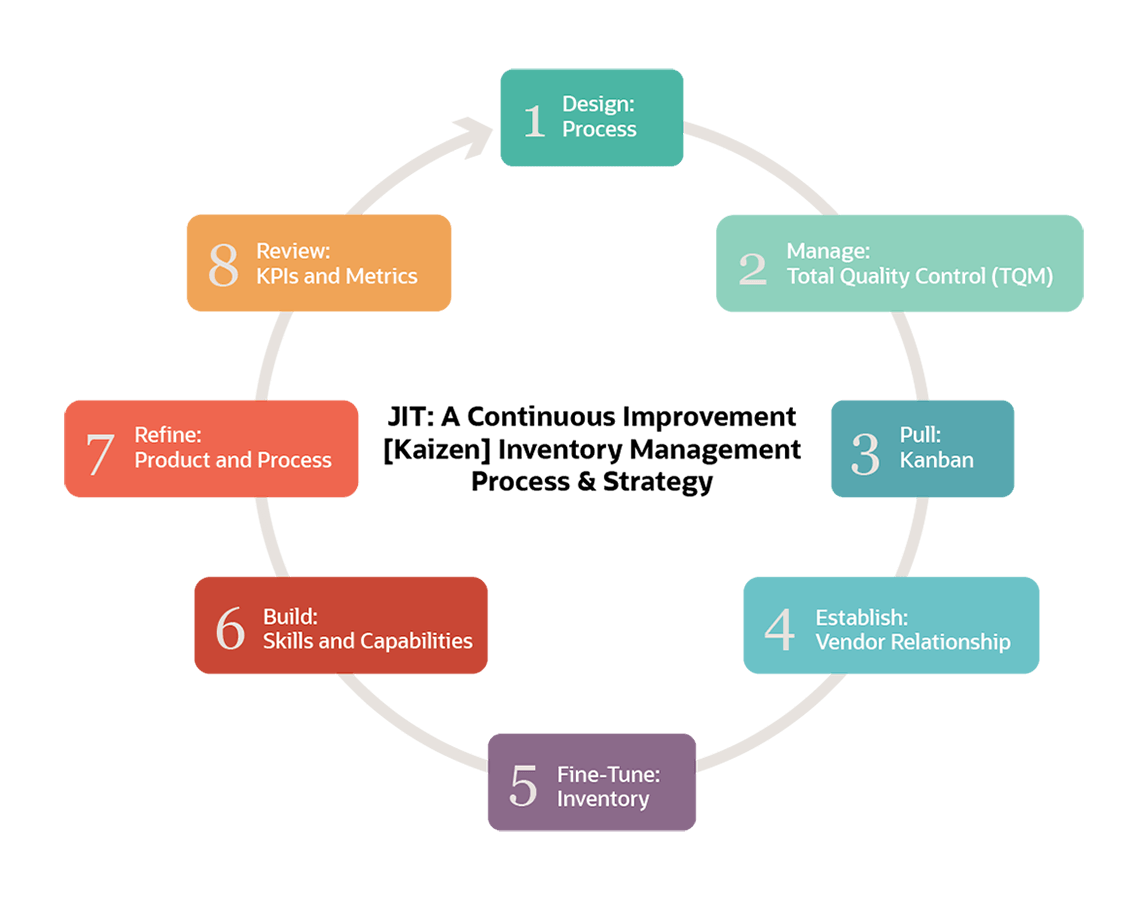

When businesses discuss "jit," they are almost invariably referring to Just-In-Time inventory management. This method represents a paradigm shift from traditional inventory models, which often involved stockpiling large quantities of products and raw materials "just in case." Instead, JIT focuses on keeping as little inventory on hand as possible. The core principle is elegant in its simplicity: you order small shipments of materials and components to replace what has just been used or sold, ensuring that goods are manufactured precisely when demand arises. This lean approach is designed to maintain a streamlined inventory, significantly enhance cash flow, and drastically reduce waste. Think of it as a finely tuned machine where every part arrives exactly when needed, eliminating the need for large storage spaces and the associated costs and risks. The strategy is to arrange the orders of raw materials in such a way that the goods flow seamlessly through the production process, minimizing idle stock. As a foundational guide would extensively review, the JIT inventory system's core lies in this precision and responsiveness. It's about optimizing the flow, not accumulating static assets.The Historical Roots of Just-In-Time

The concept of Just-In-Time didn't emerge overnight; it was the result of decades of innovation and refinement. Originating in Japan, this strategy was famously adopted by Toyota in the 1970s as a cornerstone of its Toyota Production System (TPS). Faced with limited space and resources in post-war Japan, Toyota engineers, particularly Taiichi Ohno, developed a system that prioritized efficiency and eliminated waste (muda). They observed that excess inventory was a form of waste, tying up capital, requiring storage, and masking underlying production problems. Toyota's success with JIT was phenomenal, allowing them to produce a wider variety of vehicles more efficiently and with higher quality than their Western counterparts. This success quickly garnered international attention, and the JIT philosophy began to spread globally, influencing manufacturing practices across diverse industries. It became synonymous with lean manufacturing, emphasizing continuous improvement and the elimination of any activity that doesn't add value. The "jit meaning" in this context is deeply rooted in this legacy of Japanese innovation and operational excellence.How Just-In-Time (JIT) Works in Practice

Implementing JIT is far more complex than simply reducing inventory levels; it requires meticulous planning, robust supplier relationships, and seamless information flow. Logistics, in particular, plays a pivotal role in JIT's success. It consists of identifying the steps in a production value chain, ensuring Just-In-Time (JIT) delivery of the inputs for an assembly process, coordinating the flow of information, and the scheduling of delivery. This means suppliers must be incredibly reliable, delivering precise quantities of materials exactly when and where they are needed, often multiple times a day. JIT works best for companies using repetitive manufacturing functions, where demand is relatively stable and production processes are highly standardized. This allows for predictable scheduling and a steady flow of materials. For instance, an automotive assembly line, producing thousands of identical parts, is an ideal candidate for JIT. The principles extend beyond the factory floor. Intermediate consumers often store inventory for shipment to end consumers or fulfillment centers, like retail stores. These intermediate locations often rely on JIT inventory management to ensure that products are continually moving to their final destination. This continuous movement is critical for reducing liabilities associated with holding static inventory and allowing commodities to turn a profit faster. Every step in the supply chain is optimized to minimize holding times and maximize throughput, embodying the true "jit meaning" of efficiency.Advantages of Embracing the JIT Philosophy

The benefits of adopting a JIT system are compelling, offering significant advantages that can directly impact a company's financial health and competitive edge. As previously highlighted, this method helps maintain a lean inventory, significantly enhances cash flow, and reduces waste. Let's break down these advantages further:- Reduced Inventory Costs: This is perhaps the most obvious benefit. By holding less stock, companies save on storage space, insurance, security, and the capital tied up in inventory. This directly translates to lower operating expenses.

- Improved Cash Flow: With less capital locked in inventory, businesses have more liquidity. This enhanced cash flow can be reinvested, used to pay down debt, or simply improve the company's financial flexibility.

- Reduced Waste: JIT inherently minimizes waste in several forms:

- Overproduction: Producing only what is needed, when it's needed, eliminates excess goods.

- Waiting: Efficient scheduling reduces idle time for materials and workers.

- Transportation: Optimized delivery routes and frequencies reduce unnecessary movement.

- Defects: Smaller batches mean defects are identified and corrected faster, preventing large quantities of faulty products.

- Increased Efficiency and Productivity: A lean system forces companies to identify and eliminate bottlenecks, leading to smoother production flows and higher output per unit of input.

- Enhanced Quality: With smaller batches, quality issues become immediately apparent, allowing for quicker resolution and continuous improvement. This proactive approach leads to higher overall product quality.

- Greater Responsiveness: JIT allows companies to respond more quickly to changes in customer demand or market trends, as they are not burdened by large quantities of outdated or unwanted stock.

Navigating the Challenges of JIT Implementation

While the advantages of JIT are substantial, its implementation is not without significant challenges and risks. It's a high-reward, high-risk strategy that demands precision and resilience. Unlike traditional inventory models, JIT doesn't allow for excess stock, meaning that any hiccup in material delivery can lead to costly downtime. This vulnerability is a major concern for businesses considering the shift. Another significant challenge is market unpredictability. JIT works best in environments with stable demand, where forecasting is relatively accurate. However, industries that experience sudden spikes or fluctuations in demand may struggle to keep up. A sudden surge in orders, or an unexpected supply chain disruption, can quickly expose the fragility of a system with minimal buffer stock, leading to missed deadlines, lost sales, and damaged reputation. This inherent risk highlights the need for a robust and flexible supply chain, capable of adapting to unforeseen circumstances.JIT vs. JIC: A Critical Comparison

Given the inherent risks of JIT, it's essential to compare it with its philosophical opposite: Just-In-Case (JIC) inventory management. While JIT minimizes inventory, JIC embraces the idea of keeping more inventory on hand to mitigate risks. Why does Just-In-Case (JIC) matter? For many businesses, particularly those operating in volatile markets or dealing with unpredictable supply chains, JIC provides a crucial safety net. The JIC method is controversial because it requires companies to keep more inventory on hand, which incurs loss risks, storage costs, and other expenses. These include the cost of capital tied up in inventory, obsolescence risk, and the physical costs of warehousing. However, for certain entities, these costs are deemed acceptable in exchange for continuity of operations. Hospitals, for example, cannot afford to run out of critical medical supplies; they find JIC much more feasible. Similarly, small companies, often with less leverage over suppliers or less sophisticated logistics, may also find the JIC approach more practical. In JIT, businesses don't add extra safety stocks "just in case." This is the fundamental difference. The choice between JIT and JIC depends heavily on the industry, the stability of demand, the reliability of suppliers, and the company's risk tolerance. There is no one-size-fits-all answer; the optimal strategy requires a careful assessment of a company's unique operational environment and financial capacity.Understanding Market Volatility and Its Impact

The vulnerability of JIT to market unpredictability is a critical consideration. Market volatility, often measured by indicators like the Volatility Index (VIX), can significantly impact supply chain stability. The VIX is a contrarian sentiment indicator that helps to determine when there is too much optimism or fear in the market. While directly related to financial markets, its underlying principle—the measurement of uncertainty—applies broadly to economic conditions that can disrupt supply chains. When markets are volatile, it often signals broader economic instability, which can lead to unpredictable demand, fluctuating raw material prices, and disruptions in transportation or labor. For a JIT system, which thrives on predictability, such volatility can be devastating. A sudden economic downturn might lead to a sharp drop in demand, leaving a JIT-dependent manufacturer with excess materials that are no longer needed. Conversely, an unexpected surge in demand during an economic boom could leave them unable to source materials quickly enough, leading to lost sales opportunities. This highlights the need for robust risk management strategies alongside JIT implementation, or a strategic blend of JIT and JIC where appropriate.JIT Beyond Inventory: A Broader Business Perspective

While the primary "jit meaning" in business refers to inventory management, the underlying principles of efficiency, waste reduction, and continuous improvement inherent in JIT extend far beyond the warehouse. JIT is a core component of the broader lean manufacturing philosophy, which seeks to optimize every aspect of a business operation. This holistic approach impacts not just production, but also product development, customer service, and even financial management. Anyone interested in active investing, picking stocks, or investigating a company’s financial health must know how to read financial statements. Understanding a company's adoption of JIT or lean principles can provide valuable insights into its operational efficiency, cost structure, and ultimately, its profitability. Companies that effectively implement JIT often demonstrate stronger financial performance due to reduced overheads and improved cash flow.The Importance of Financial Statements and Key Metrics

The success or failure of JIT, and indeed any operational strategy, is ultimately reflected in a company's financial statements. An operating statement, also known as an income statement, is important because it provides a snapshot of a company's revenues, expenses, and profits over a period. Key metrics like Earnings Before Interest and Taxes (EBIT) matter significantly because they indicate a company's operational profitability before the impact of financing and taxes. For example, if EBIT is $200,000 while net income is $100,000, it tells a story about how much profit was generated from core operations before other financial considerations. Operational efficiency, often boosted by JIT, directly impacts these figures. A company that successfully reduces inventory holding costs and waste through JIT will likely see improved gross margins and, subsequently, higher EBIT and net income. Consider Bob's Bakery: in order to break even, Bob’s bakery would need to sell 875 loaves of bread per month. If it sells fewer than 875 loaves, the business’ revenue would not cover its expenses, so Bob would lose money. JIT principles, applied to Bob's bakery, would mean ordering flour and ingredients just as they're needed, minimizing spoilage and storage costs, thereby helping Bob reach his break-even point more efficiently.Understanding Fiscal Quarters and Company Reporting

For investors and analysts, understanding a company's financial health also involves scrutinizing its performance over specific periods. What is a fiscal quarter? It's a three-month period that companies use for financial reporting. Knowing where to find quarterly reports is essential for assessing a company's ongoing performance. Discovering everything about fiscal quarters in 2021 and beyond means staying informed about how companies are managing their operations and finances. A company's quarterly reports will reveal how well its inventory management strategies, including JIT, are performing. Lower inventory levels on the balance sheet, coupled with strong sales figures, can indicate successful JIT implementation. Conversely, rising inventory levels without a corresponding increase in sales might signal inefficiencies or a shift away from lean practices. This transparency in reporting, facilitated by fiscal quarters, allows stakeholders to gauge the effectiveness of a company's operational strategies, including its commitment to the "jit meaning" of efficiency.The "Jit" Slang: A Deeper Dive

Having thoroughly explored the business "jit meaning," let's circle back to its more informal, yet equally prevalent, usage. As noted, the term "jit" is a piece of slang commonly used by Generation Z to refer to a young person, typically a teenager, or someone who is inexperienced or new at something. This usage is informal and often appears in casual conversations, social media, and online gaming. It's a versatile term that can be used playfully, sometimes with a hint of exasperation, or simply as a descriptor. The Redkiwi English Guide provides excellent context, meaning, origin, and examples for this particular slang phrase. Interestingly, words often have complex linguistic histories and forms across different languages or dialects. While not directly related to the English slang or business "jit," it's worth noting how deeply words can be analyzed in linguistics. For instance, some linguistic data might show a word "jit" with various conjugations, such as "jit jit 2nd singular jitst jitst 3rd singular jit jit plural / dual jit jit perfect pluperfect 1st singular haa jiten her jiten 2nd singular heest jiten herst jiten 3rd singular heer jiten her jiten plural / dual haa jiten her jiten future (skel) future (wel) 1st singular skel jit wel jit 2nd singular sket jit wet jit 3rd singular skel jit wel." This detailed breakdown, while perhaps from a different linguistic context, underscores how a seemingly simple word can have intricate grammatical structures or multiple historical derivations, further highlighting the importance of context when interpreting any term, including the various "jit meaning" applications we've discussed.Conclusion

The "jit meaning" is a remarkable example of how a single word can embody vastly different concepts depending on its context. From a casual slang term used by younger generations to describe a young or inexperienced person, to a sophisticated and transformative inventory management system known as Just-In-Time, "jit" truly showcases the dynamic nature of language. In the business world, JIT represents a relentless pursuit of efficiency, waste reduction, and optimized cash flow, a strategy that has profoundly impacted global manufacturing and supply chains since its popularization by Toyota. Understanding both facets of "jit" is essential. For businesses, mastering the principles of Just-In-Time can lead to significant competitive advantages, though it demands meticulous planning and a robust supply chain to navigate its inherent risks. For individuals, recognizing the slang usage ensures smoother communication in contemporary social settings. Ultimately, whether you're discussing operational strategy or casual conversation, the context is king in deciphering the true "jit meaning." We hope this comprehensive guide has illuminated the diverse interpretations of "jit." What are your thoughts on the dual nature of this word? Have you experienced the benefits or challenges of JIT in a business setting, or perhaps encountered the slang in everyday life? Share your insights in the comments below! If you found this article insightful, consider sharing it with others who might benefit from understanding the nuanced meanings of common terms, and explore our other articles on business efficiency and linguistic trends.- What Happened To Buford Pussers Son The Untold Story Behind The Legend

- Exploring The Fascinating World Of Yololary Spiderman

- Bonnie Bruise

- Sophie Rain Only Fans Leak

- Barron Trump Height Disease

JIT or just in time as effective inventory management method outline

Just-in-Time (JIT) Inventory: A Definition and Comprehensive Guide

.png)

¿Qué es Justo a Tiempo? - Just In Time (JIT) | Características e